|

Growing Micropropagated Sweetpotatoes

|

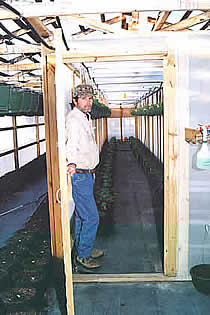

We

have a separate greenhouse for each variety that we get from the NC

State University Micropropagation Unit. A wood-frame greenhouse--

20'X80' - 1/3 center area is screened in for mother plants. |

|

Each

greenhouse features electricity on thermostats and automatic timers

for water and fertilizing. |

|

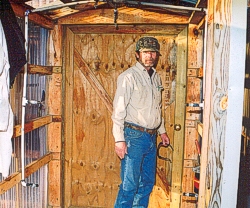

Before

entering each greenhouse, everyone goes though a double entry area

for sterilization with a fogging system that complete covers the body

to eliminate insects and diseases getting into the greenhouse. We

don't feel it's enough to just step in a clorox-filled tub.

|

|

At

the start of each growing season, we sterilize everything with a Clorox/

Oxidate/fungicide/

spore killer mixture to make sure everything is spic 'n' span and

ready for new mother plants to be micropropagated. |

|

|

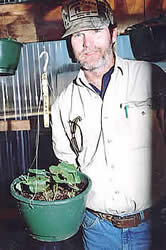

Around

the 1st week of Feb. we pick up plants in 4" clay pots from the

NC State MPU. We get 50 plants of four different varieties with a

color-coded label for each variety. |

|

We

immediately re-pot the mother plants into 3-gallon pots or hanging

baskets that were previously fillled with special potting soil and

watered thoroughly. We want to make sure our new plants can grow and

not be root bound. |

|

As

the mother plant grows runners, we spray alcohol on clippers before

making each cut at the second node joint to make sure we are not transmitting

any viruses. |

|

Jessica

places 7 to 8 second-node cuttings in a hanging basket, which are

hung in the greenhouse just outside the caged mother plant room |

|

These

first daughter cuttings, with each pot labeled to show what mother

plant it came from, continue to grow . |

|

|

|

| As

they grow, Jim and Jimmy take 2 node cuttings from each first daughter

plant, which will be planted in another greenhouse with the same variety.

|

|

Each

of our greenhouses has ground cover and gravel on the floor for drainage,

as well as drain lines that run underground to remove any standing

water. |

|

Jim

and Jimmy punch holes in the soil ready for second daughter cuts. |

|

Jim

and Jessica spacing and planting second daughter cuts in 6" rows,

with each plant about 4" apart. We have about 18-20,000 plant

capacity in each greenhouse. |

|

Jim

adjusts irrigation pipes to water second daughter plants. |

|

Second

daughter plants are now ready for transplanting and making seed stock

in the field. |

|

Prior to planting,

we sample and meter the soil in all our sweet potato fields to determine

what nutrients are needed to grow a good crop.

|

|

|

| Starting

about the first or second week of May, plants are cut every 8-9 days

for 7-10 weeks for transplanting in our fields, We practice select

cutting, using clippers to get the biggest plants to grow. We give

the smaller plants time to get bigger before weekly cuttings and transplanting

in the field. |

|

Irrigation

is key to growing quality plants and assuring a good stand. To get

a good, uniform stand, a grower must irrigate if there has been no

rainfall.

|

|

Applying sidedress

fertilizer four weeks after transplanting will help ensure us of a

good high yield of uniform #1 sweet potatoes. |

|

Moving

vines 8-10 days before digging with plow. |

|

|

Digging

with 2-row plow

|

|

|

|

Potatoes

upturned by digger.

|

|

Bins

and buckets are sterilized before harvest time. Harvesting crew separates

seeds from #1's, carefully handling them as they're placed in bins

for storage. |

|

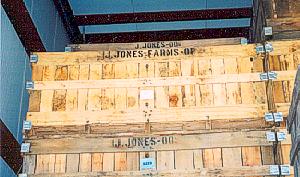

Curing

boxes

(each holds 40 bushels)

of sweetpotatoes on truck.

|

In the curing shed, sweet potatoes are cured and stored over winter.

They are kept for 4 to 5 days at 85 degrees and 85 percent humidity

and then down to 55 degrees at 85 percent humidity for the duration

of the time in the curing barn. |

|

With the right

micropropagated seeds or plants and, God willing, mother nature's

cooperation we will have the very best crop of sweetpotatoes under

our rows.

|

|

|

We

grow our micropropagated 1st generation seed potatoes in field beds

to make 2nd generation plants, which become our commercial potatoes

and 2nd generation seed for sale to other growers. We start by placing

the seed potatoes as close as we can without stacking. |

|

We place 2 lines

of drip tape for irrigation as we cover seed beds with soil. |

|

|

The

beds are covered with plastic

|

|

|

Jim's

wife, Barbara, punches holes in the plastic to allow air to circulate

on the plant bed. Along with water, we add nutrients once a week through

irrigation drip tape. |

|

|

|

G-2

plants come from our G-1 field seed beds. They are hand selected to

ensure uniform, healthy plants that will produce high yielding good

quality G-2 sweet potatoes. |

Micropropagation

Brings Sweet results

to North Carolina Growers

With farmers in dire

need of something to generate bank deposits after tobacco’s lean

years and the damage from the 1999 hurricane season, micropropagated sweetpotatoes

just might be the crop to boost cash flow in years to come.

The sweetpotato, North

Carolina’s official vegetable, brought in $60 million in cash receipts

last year from the more than 37,000 acres grown on the western edge of

our state’s coastal plains, home to much of the nation’s crop.

|

Due mostly to

seed stock improved by the College of Agriculture and Life Sciences’

Micropropagation Unit (MPU) at N.C. State University, a total of

about 40,000 coastal plains acres probably will go to sweetpotatoes

this year, says Dr. Zvezdana Pesic-van Esbroeck, MPU director.

Micropropagation

is the carefully controlled generation of plants from a few cells

of an original plant, which allows massive plant regeneration from

originals that have been checked for disease and other problems.

The MPU meets

the increasing demands of North Carolina’s fruit and vegetable

industries for pathogen-free, virus-indexed, true-to-variety, asexually

propagated stock plants.

N.C. State researchers,

Cooperative Extension specialists and county agents, who in 1988

introduced the first micropropagated sweetpotatoes into North Carolina

fields, strive to hold and improve the plant’s national market

share. That share already is a healthy 40 percent, say statistics

from the North Carolina Sweetpotato Commission Inc.

|

|

To produce micropropagated

plants, researchers such as Pesic-van Esbroeck and Dr. Marilyn Daykin,

a tissue culture specialist, grow tiny groups of meri-stematic cells

— located at the leading edge of the plant’s growth —

under controlled laboratory conditions at the MPU, generating small

plants called mericlones.

Mericlone production

in the lab bears no relation to the process that creates transgenic,

or genetically modified, organisms.

|

"No sweetpotato

mericlone genes are altered or transferred from one plant to another,"

Pesic-van Esbroeck says.

Researchers check

the clones, and pathogen-free mericlones are multiplied — "increased,"

in growers’ language —through in-vitro techniques.

Later, scientists

make cuttings to further increase the mericlones in isolated, insect-free

greenhouses at the Sandhills Research Station in Montgomery County.

|

The MPU’s

sweetpotato research is part of a continuing College effort to assist

growers. College departments such as Plant Pathology, Horticultural

Science and Entomology have cooperated with Extension and growers

to help the sweetpotato buck stiff competition from other states.

Extension workers

and researchers also help protect the crop from diseases such as

the russet crack strain of the feathery mottle virus and against

genetic drift, which happens if several generations of the same

mother plant’s roots — not the preferred vines —

are used for seed stock and replanted in the same field.

"The MPU

avoids that problem through cloning the sweetpotato’s vine

at the spot where it’s growing, the meri-stem," says Pesic-van

Esbroeck. "A virus and other plant pathogens can be present

everywhere in an infected plant but only rarely in the meristematic

tissue."

|

Since the cleanest

stock comes directly from the MPU, North Carolina Foundation Seed Producer

growers must refresh their stock from the N.C. State greenhouse annually.

Only that stock guarantees commercial sweet potato growers hill-selected,

tissue-culture-generated, field-evaluated stock. But one such plant can

translate into millions of sweetpotato plants in the field in a year.

|

The field is

yet another place where researchers exercise quality control. Breeders

Dr. Craig Yencho of the Vernon James Research and Extension Center

in Plymouth, Kenneth Pecota of the College’s Horticultural

Science Department, growers and others walk through harvested plantings

yearly, while roots still are attached. They examine hundreds of

plants, looking for the best. They also evaluate the lab’s

existing mericlones in several fields to test for evidence of disease

and genetic drift.

Dr. Charles

Averre, a retired plant pathologist, helped develop the micropropagation

system at N.C. State. Averre; Dr. Robert Milholland, retired plant

pathology professor; Dr. Jonathan Schultheis, Extension horticulture

specialist; and Bill Jester, an Extension area specialist, developed

and demonstrated micropropagation procedures compatible with existing

North Carolina Foundation and Certificate programs. These procedures

ensured that sweetpotatoes stayed disease-free and stopped genetic

drifts.

|

"But the most

important thing about this program," says Averre, "is to give

our growers quality roots. Then they will have a comparative edge, and

that’s what pays off."

|

NC

MPU Lauren Hix came out to inspect our plants. Protocol of NC Crop

Improvement and Micropropagation Unit, inspected regularly once per

month. During these unscheduled visits, they inspect greenhouses,

look at plants, check for cleanliness, good housekeeping, etc. |

|